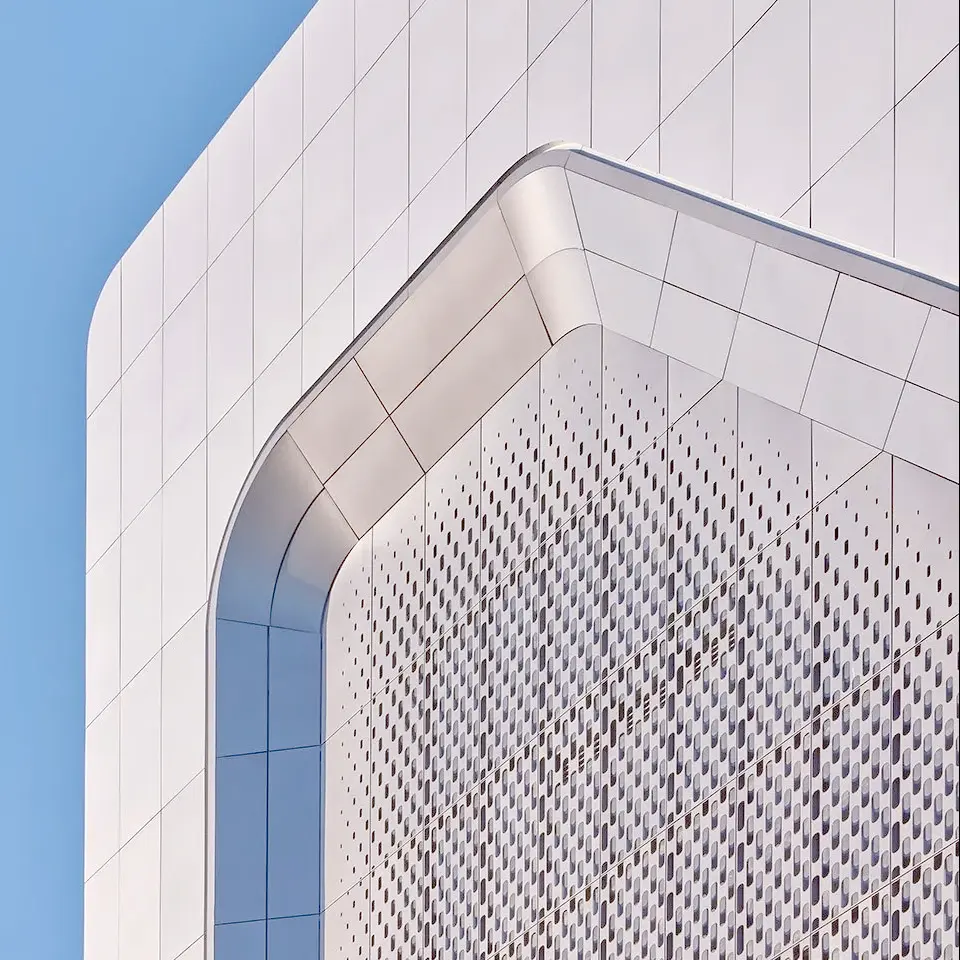

Perforated metal sheets are precision-engineered facade materials that have become a favorite among architects and property owners alike. Through CNC-controlled cutting and punching processes, these sheets can be crafted into a variety of patterns, enhancing a building’s exterior while adding a distinct personality. Not only are they wear-resistant and corrosion-proof, but their excellent decorative properties also make them an ideal choice for modern architectural facades.

1. Main Types of Perforated Metal Sheets

1.1 By Material

Perforated metal sheets come in various base materials including aluminum, steel, copper, and iron. Among them, perforated aluminum sheets are particularly valued for their diverse surface treatment options such as anodizing, powder coating, and brushing, offering a wide range of colors and textures to meet different design requirements. Stainless steel perforated sheets are known for their high strength and durability, making them suitable for modern projects that demand robust performance. Galvanized steel perforated sheets, on the other hand, offer cost-effective practicality and are widely used in large-scale industrial or commercial facilities.

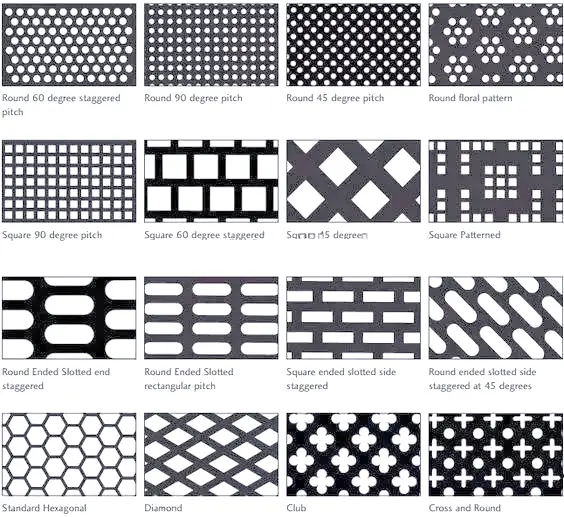

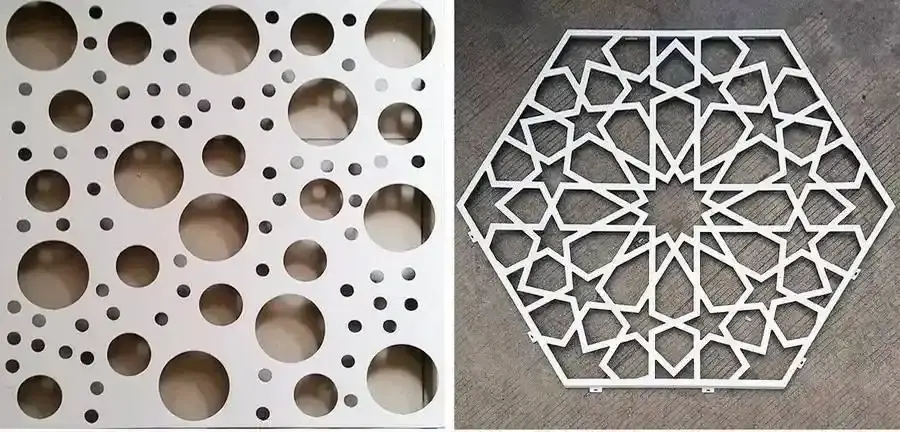

1.2 By Perforation Pattern

Patterns can be classified into uniform perforation, gradient perforation, and decorative perforation. These hole patterns are carefully designed to achieve varying degrees of visual transparency and functional performance. Options include round, square, slotted, diamond-shaped holes, and even customized patterns such as logos or artistic designs. The layout of the holes—whether linear, staggered, or gradient—also significantly impacts the visual rhythm and functionality of the sheet.

1.3 By Panel Shape

Based on shape, perforated metal sheets can be flat rectangular panels, customized profiles, or corrugated (bent) panels. Flat panels are popular for their simple manufacturing process and cost-effectiveness. However, as the panel size increases or the perforation ratio rises, structural strength may decline. To compensate, designers may reduce panel size, increase thickness, or add support frames on the back—though such reinforcements might affect the visual appearance.

Corrugated perforated panels increase structural strength by adding folds or ridges, reducing the need for visible substructures. The depth and angle of the folds can be adjusted to control the level of transparency and enhance the play of light and shadow on the facade.

2. Common Perforation Methods

CNC Punching: This traditional and widely used method uses punching machines to create desired hole shapes in metal sheets.

Laser Cutting: A modern technique known for its high precision and flexibility, though it tends to be more expensive and complex.

3. Advantages of Perforated Metal Sheets for Facade Applications

The popularity of perforated metal sheets in facade design stems from their exceptional aesthetic and functional benefits.

Aesthetic Value:

Perforated designs create captivating light and shadow effects. During the day, sunlight filters through the holes to project dynamic shadow patterns; at night, internal lighting shines through, producing a starlit appearance. This interplay between light and architecture adds life and identity to the building’s exterior.

Functional Benefits:

Ventilation: Perforated facades facilitate air circulation, improving internal pressure balance and reducing wind loads.

Shading: Precisely calculated perforation ratios allow natural light to enter while minimizing solar heat gain, enhancing energy efficiency.

Acoustic Performance: Specific hole types combined with acoustic backing materials make perforated metal sheets effective noise barriers—ideal for buildings near airports or highways.

Durability & Maintenance: With excellent weather resistance, especially when coated with PVDF or other protective finishes, these sheets resist UV rays, dirt, and corrosion. Routine rinsing with clean water is often sufficient for upkeep, making them a long-lasting, low-maintenance cladding solution.

4. Key Design and Installation Considerations

Successful perforated metal sheet facade systems begin with thoughtful design. The perforation ratio—defined as the percentage of hole area relative to total sheet area—is a critical factor:

- Low (under 20%): Offers privacy and sun-shading.

- Medium (20%-40%): Balances transparency and function.

- High (above 40%): Delivers lightness and openness.

Designers must also consider environmental factors like dominant wind direction, sunlight path, and nearby noise sources.

From a structural standpoint, panel thickness, reinforcement ribs, and support systems must be carefully planned. Supporting structures—typically made of aluminum or steel—require precise spacing calculations. Fastening methods (screws, clips, etc.) must ensure both structural integrity and visual appeal, especially for visible components.

Proper installation is vital. Surface alignment and accurate field measurements are necessary to ensure pattern continuity. The usual sequence follows bottom-to-top and center-to-sides to minimize cumulative errors. Attention must be paid to joint uniformity, panel flatness, drainage, and high-altitude safety protocols.

5. Conclusion

In conclusion, perforated metal sheets offer a perfect combination of aesthetic flexibility, structural performance, and practical functionality, making them a top choice for modern architectural facades. From material selection and perforation style to installation techniques and environmental benefits, every detail contributes to a long-lasting, visually striking exterior solution. As architectural trends continue to evolve, perforated metal sheets will remain at the forefront—bringing creativity, sustainability, and engineering excellence together in one powerful material.