Product Overview:

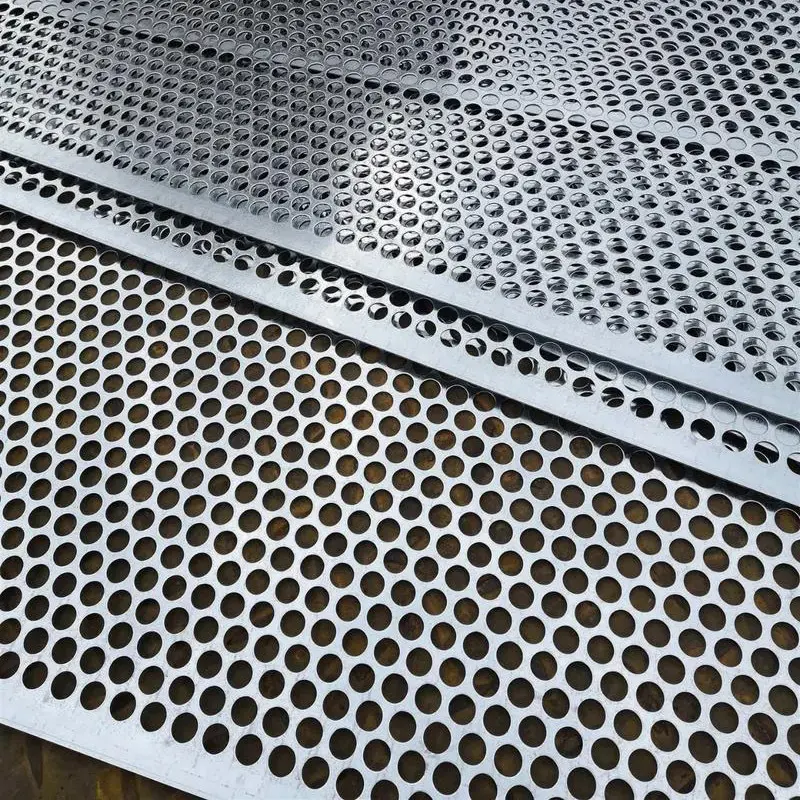

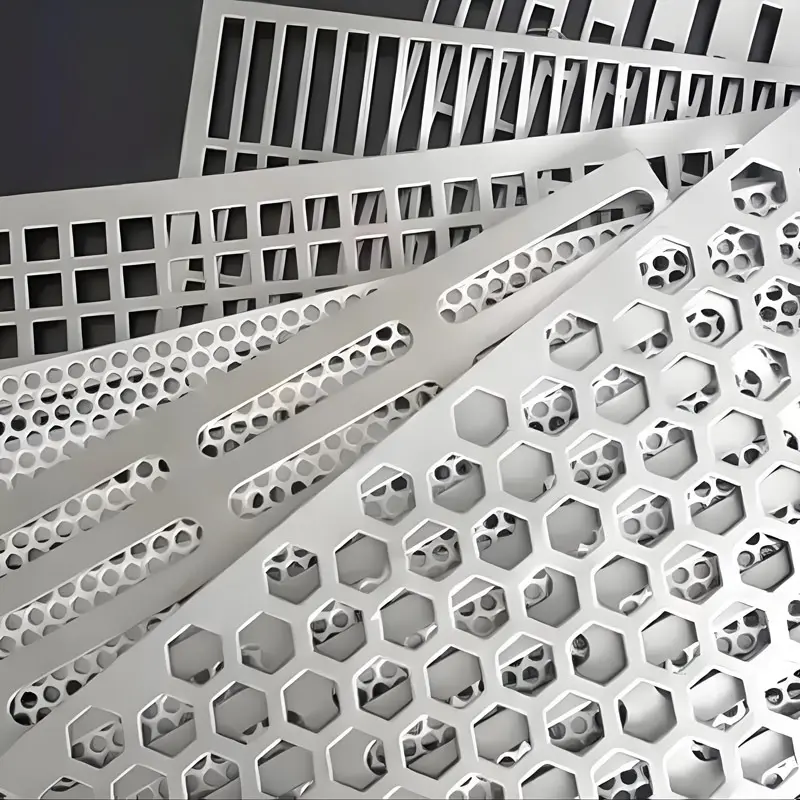

Perforated metal sheet is a multifunctional material that forms regular or customized holes on metal sheets through precision stamping, laser cutting or CNC drilling. It has high strength, light weight and artistic beauty, and is widely used in architectural decoration, industrial screening, sound absorption and noise reduction, ventilation and heat dissipation, and modern design.

Key Features:

Diverse Material Options

Offered in stainless steel, aluminum, galvanized steel, copper, and other materials to meet various requirements such as corrosion resistance, weather durability, and aesthetic appeal.

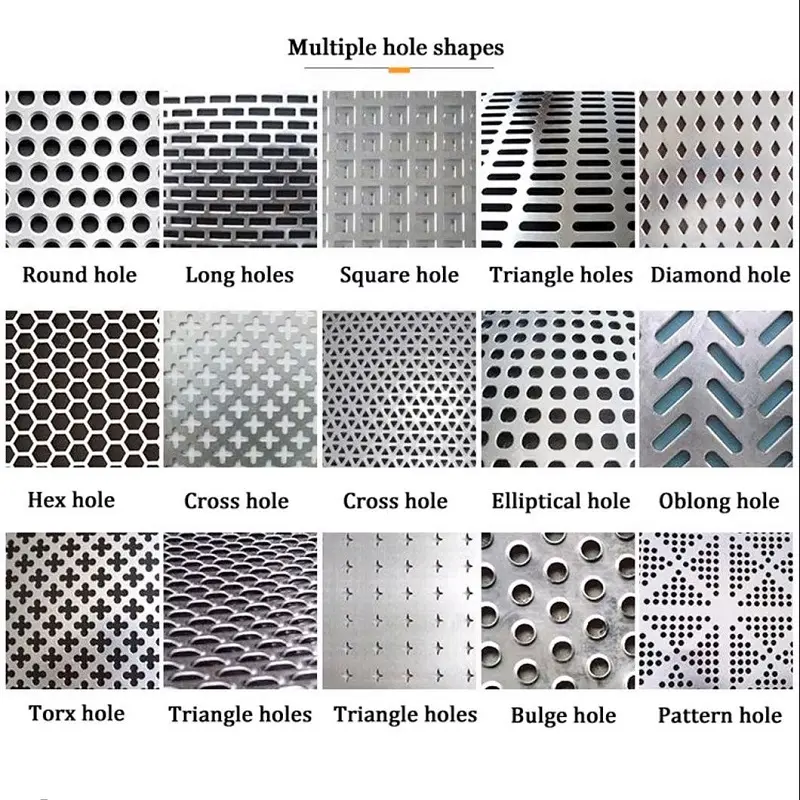

Customizable Hole Patterns

Available in round, square, hexagonal, and irregular hole shapes. Hole diameter, pitch, and layout (e.g., gradient, wave, or other artistic patterns) can be fully customized to suit your design and functional needs.

Superior Performance

Excellent ventilation and heat dissipation capabilities. Certain perforation designs enhance acoustic properties, offering sound absorption and noise reduction. Durable, impact-resistant, and easy to cut, bend, and install.

Versatile Surface Finishes

Options include powder coating, anodizing, brushed finish, mirror polish, and more—perfect for both industrial-style applications and upscale architectural aesthetics.

Applications of Perforated Metal Sheets:

Perforated metal sheets are widely used across various industries due to their functional versatility and customizable patterns. Common applications include:

- Building facades – used as cladding elements for sun shading, ventilation, and aesthetic appeal

- Ceiling systems – offering acoustic performance and visual enhancement in commercial interiors

- Interior partitions and space dividers – providing airflow and light diffusion while maintaining separation

- Fencing and security enclosures – durable and effective for both protection and decoration

- Architectural decoration – used for feature walls, screens, and artistic installations

- Machine guarding – ensuring operator safety in industrial environments

- Ventilation and air filtration – promoting airflow while blocking dust or debris

- Filtration components – applied in HVAC systems, food processing, and chemical industries

Specifications:

| Parameter | Details |

|---|---|

| Material | Stainless Steel, Aluminum, Galvanized Steel, Copper |

| Sheet Thickness | 0.3 mm – 6.0 mm |

| Hole Shape | Round, Square, Hexagonal, Slotted, Custom (e.g., triangle, star) |

| Hole Size (Diameter) | 0.5 mm – 20 mm (customizable) |

| Open Area | 10% – 60% (depends on hole size and spacing) |

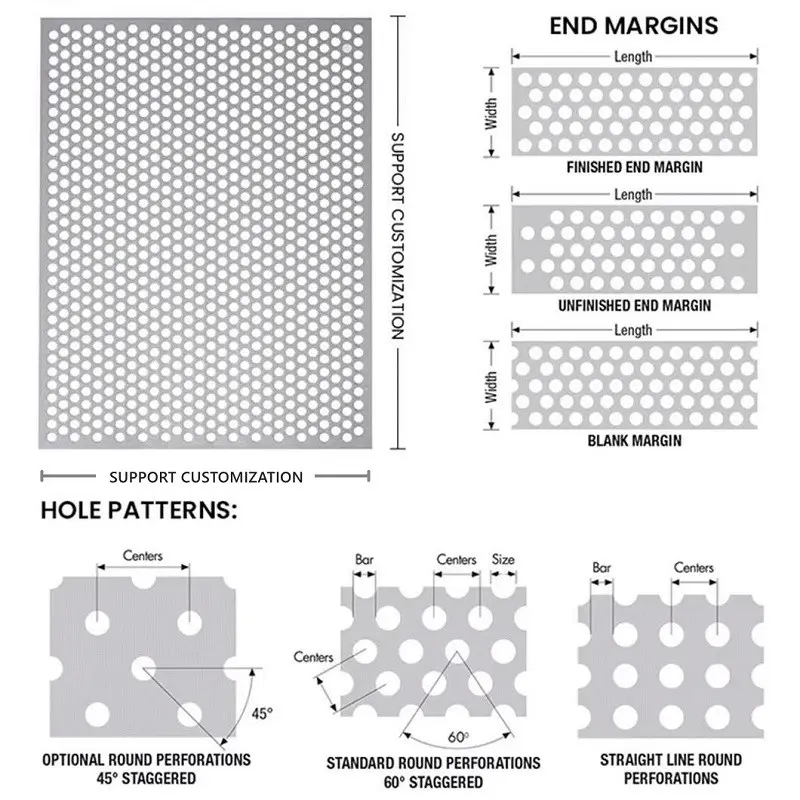

| Pitch (Hole Spacing) | Customizable: staggered or straight pattern |

| Sheet Size | Standard: 1000×2000 mm, 1220×2440 mm; custom sizes available |

| Surface Treatment | Powder Coating, Anodizing, Brushed, Mirror Polish, Galvanized, PVDF Coating |

| Pattern Layout | Straight row, staggered row, diagonal, or custom decorative patterns |

| Tolerances | ±0.1 mm (depends on material and production process) |

| Edge Type | Plain edge, margin, or customized |

More details: