As the name suggests, perforated metal panels are metal sheets that are processed with regular patterns of holes using modern techniques such as mechanical punching and CNC cutting. These perforations form unique surface textures or patterns, offering both visual and functional design elements.

After perforation, metal sheets can undergo various surface treatments based on project needs, including electroplating, powder coating, and brushing.

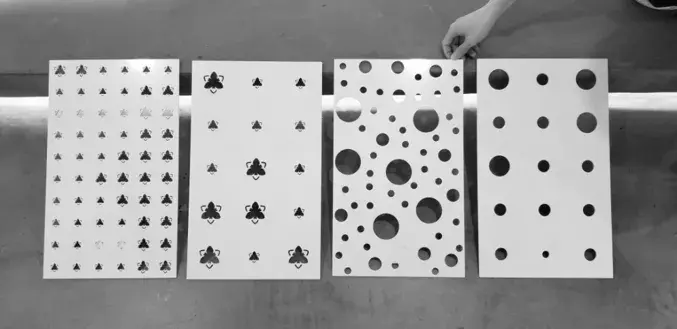

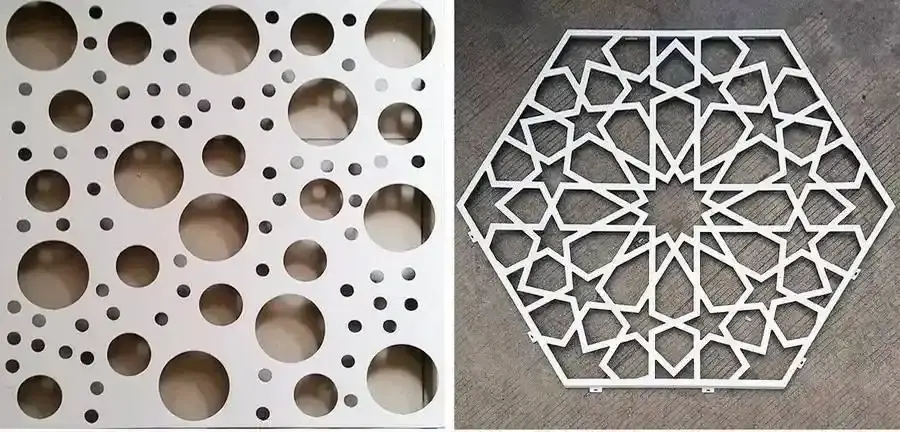

In the past, perforated panels were mainly produced through mechanical stamping, which limited them to creating relatively uniform and regular hole patterns. With the advancement of CNC technology and cutting methods like plasma, laser, and waterjet, today’s perforated metal panels can achieve intricate, almost digitally engraved patterns.

For exterior applications, base materials typically include aluminum alloy sheets, copper (alloy) sheets, stainless steel, and weathering steel. These materials are chosen for their strength and rigidity, and among them, aluminum alloy is the most widely used in architectural facades.

When the perforation size and open area are high, the structural stiffness of the panel can be reduced. To compensate, stiffeners are often added to the back of the panel. However, these can cast visible shadows, so in design, it is recommended to limit the panel width—such as keeping aluminum panels around 1 meter wide—or to increase thickness for broader panels.

Perforated metal panels offer architects great flexibility in expressing design textures. Variations in hole density, diameter, and surface undulation can create diverse facade effects.

In renovation projects or for new buildings with irregular facades, perforated panels can help unify the appearance by covering elements like windows, walls, and structural beams, resulting in a more cohesive overall visual effect.

When applying perforated panels, it is important to consider factors such as ventilation, natural light, and visibility between interior and exterior. In some cases, special treatment may be needed for emergency escape or rescue windows.

Profiled Perforated Metal Panel

For panels with large hole diameters and high perforation rates, corrugating the sheet can increase structural stiffness while also adding visual texture. For expensive materials like copper, corrugation can reduce the required thickness, helping to lower material costs.

Perforated Metal Mesh Panels Laminated with Glass

Perforated metal sheets can also be embedded within laminated glass to control transparency, surface color, and visual patterns through different open-area percentages.

Design Considerations for Architects Using Perforated Metal Panels:

- Scale and Visibility: The perception of perforations differs between close-up (human scale) and building scale. A hole of 5mm vs. 6mm is noticeable up close but not from afar. For facade viewing from 20 meters or more, a hole diameter of around 20mm is recommended. Once the hole size is determined, the open area should be designed according to the desired visual effect.

- Hole Distribution: Open area percentage can be calculated based on the center-to-center distance between holes. These can be arranged in a grid or staggered triangular pattern, each yielding slightly different visual effects.

- Panel Size and Reinforcements: Try to keep at least one dimension of the panel narrow to avoid requiring rear stiffeners or overly thick material. If large panel sizes and reinforcements are necessary for strength or flatness, consider perforating or spacing the pattern to accommodate the stiffeners, keeping them outside the perforated area.

- Pattern Consistency: If there are standardized panel sizes, the perforation pattern should take actual dimensions into account to avoid incomplete holes at the edges or irregular blank areas.

- Panel Transitions: When adjacent panels meet, be mindful of spacing or joint gaps to ensure pattern alignment and avoid misalignments or pattern interruptions across panel boundaries.