Perforated steel sheet metal is a versatile and widely used material across construction, industrial, and decorative applications. Known for its strength, durability, and customizability, perforated steel sheets are formed by punching or laser-cutting holes into steel plates in various patterns and sizes.

In this article, we’ll explore the types, applications, and benefits of perforated steel sheet metal, and how you can customize it for your project.

What Is Perforated Steel Sheet Metal?

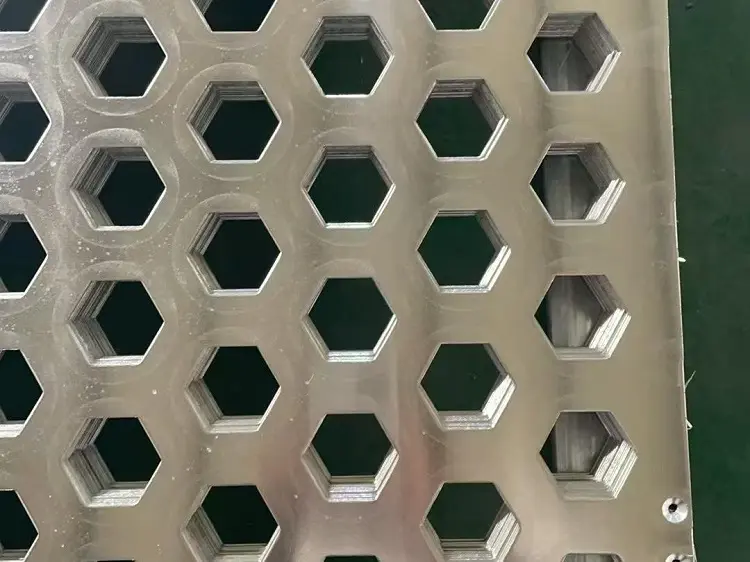

Perforated steel sheet metal is made by punching holes into flat steel plates using CNC punching machines or laser cutting technology. The holes can be round, square, slotted, or custom-shaped, depending on the design requirements.

Key Features:

- High strength and rigidity

- Good ventilation and light filtration

- Corrosion resistance (especially with galvanized or powder-coated finish)

- Available in mild steel, galvanized steel, and stainless steel

Main Applications of Perforated Steel Sheet Metal

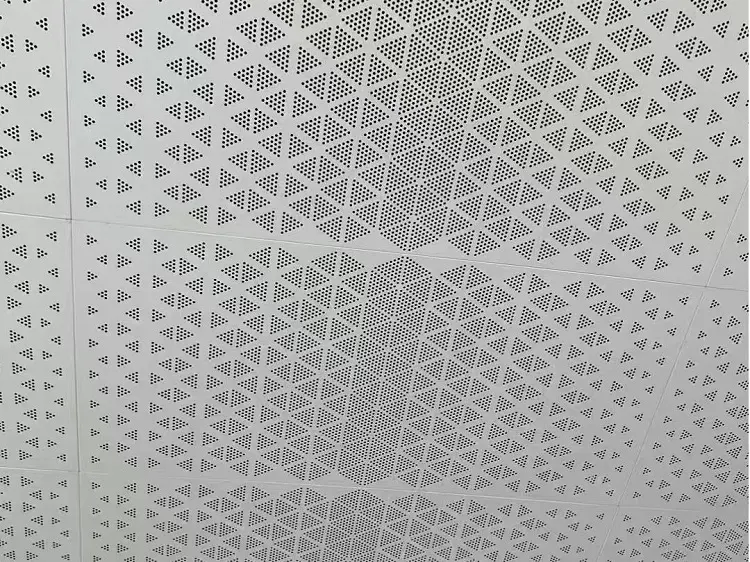

(1) Architecture and Decoration

Facade and exterior wall cladding: Enhances architectural aesthetics while providing ventilation and sun-shading functions.

Interior ceilings and partitions: Improves spatial openness with both decorative and functional value.

Railings and safety screens: Commonly used in staircases, balconies, and server rooms, offering safety and airflow.

(2) Industrial Applications

Screening and filtration: Used in vibrating screens, mining screens, grain processing, etc. Various hole sizes help control filtering precision.

Machine guards: Provide effective ventilation while preventing foreign object intrusion.

Sound insulation and noise reduction: Applied in acoustic walls, generator rooms, and more to reduce noise transmission.

(3) Home and Commercial Use

- Furniture design (e.g. partitions, storage racks)

- Retail display racks and signboards

- Ventilation and heat dissipation parts (e.g. appliance covers, air conditioning vents)

Hole Patterns & Types

We offer a wide range of hole patterns and sheet configurations:

| Hole Shape | Description |

|---|---|

| Round holes | Most common and cost-effective |

| Square holes | Clean, modern look |

| Slotted holes | Ideal for air flow and drainage |

| Custom shapes | Star, hexagonal, triangle, decorative |

Perforation spacing (pitch), open area ratio, and sheet thickness can all be customized based on your needs.For more details, click: 《Perforated Metal Sheet》

Surface Treatments

To enhance corrosion resistance or achieve aesthetic goals, perforated steel sheets can be treated with:

- Galvanizing (zinc-plated)

- Powder coating

- Painting

- Brushed or polished finishes

Custom Fabrication Services

We offer full-service perforated steel fabrication including:

- CNC punching and laser cutting

- Sheet metal bending and rolling

- Welding and assembly

- Surface finishing and packaging

Whether you need small-batch prototypes or bulk production, we support OEM & ODM projects for global clients.